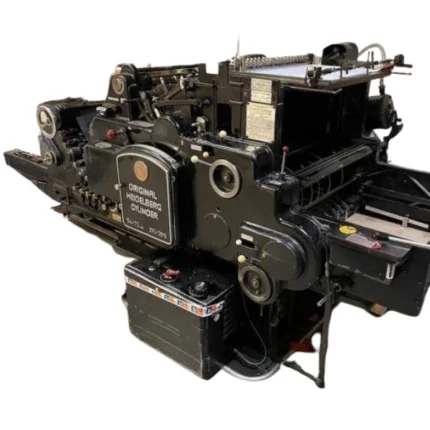

Bobst Autoplatine Speria 106 E 2006

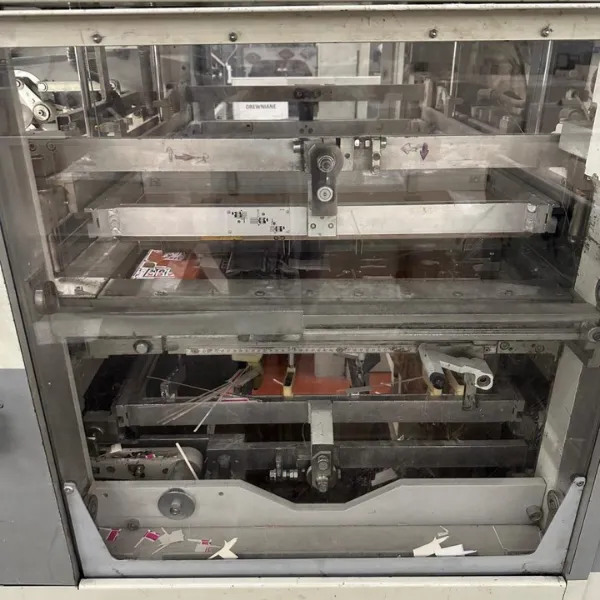

The Bobst Autoplatine Speria 106 E is a high-performance automatic die-cutting machine designed for paperboard and corrugated board applications. Built for precision, reliability, and fast job changeovers, it is an ideal solution for commercial and packaging converting operations.

The Bobst Autoplatine Speria 106 E is engineered to deliver consistent die-cutting accuracy and high productivity for demanding production environments. Equipped with Bobst’s Centerline system, the machine enables fast and repeatable job setups, significantly reducing make-ready times.

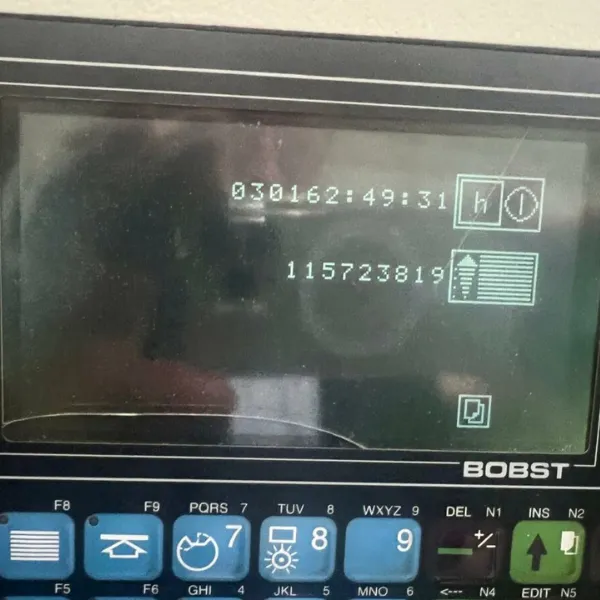

The machine operates with the Bobst Electronic Control System C.U.B.E., a microprocessor-based operating system that allows the operator to control, visualize, and monitor all machine functions from a centralized interface. Advanced sheet travel control and precise centering systems ensure smooth and reliable sheet handling throughout the process.

From feeder to delivery, the Speria 106 E is designed to handle paper, paperboard, and corrugated board efficiently, making it suitable for a wide range of packaging and die-cutting applications.

Standard Equipment

Machine

- Centerline system for quick job changeover

- Electronic device for sheet travel control

- Adjustable centering at stripping station

- Control cabinet cooling unit

- Bobst Electronic operating system C.U.B.E. (Control Unit Bobst Electronic)

- Main motor with frequency converter control

Feeder

- Pile tray with handle for manual lateral pile correction during production

- Sheet synchronization device for accurate front lay positioning at standstill

- Pile lifting controlled by Pressfoot

- Rear pile guides (OS and OOS)

- Adjustable side blowers with Centerline marks

- Suction unit

Feed Table

- Anti-static stainless steel covered feed table

- Feed table inlet with lateral ramps

- 4 front lays adjustable in pairs with front register control

- “Pull” guide (OS) adjustable with Centerline marks and side register control

- Double sheet detector

- Support plates at platen station entry

- Sheet hold-down device guiding sheets to front lays

- Upper frame with manual lifting device

- Upper transport equipment for paper, paperboard, and corrugated board

- Transport belts with lateral guidance and automatic tension system

Platen

- Gripper reopening device

- Equipment centering and locking system

- Locking of the chase against the upper beam

- Cutting force measurement with strain gauge

- 1 synthetic material supporting plate

- 1 upper chase (fixed bottom plate)

- 1 cutting plate

Delivery

- Pile tray

- Front jogger

- Adjustable rear and side joggers with Centerline marks

- Braking brush

- Manual non-stop rack

Available Extras:

- B Machine

- B-1 Elevated machine

- C Feeder

- C-4 Manual non-stop device

- E Platen

- E-5 Compensating plate

- E-55 Adjustable supporting plate centerings (micro adjustment)

- F Waste Stripping Station

- F-31 Upper pull-out frame quick-locking device

Applications

- Die-cutting for folding cartons

- Packaging and converting operations

- Paperboard and corrugated board processing

- Commercial and industrial packaging production

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.