Polar 92 E Guillotine Cutting Machine – 1996

The Polar 92 E (1996) is a heavy-duty automatic guillotine cutting machine designed for professional print finishing and post-press operations. Equipped with an air table, side tables, TFT monitor, programmable control, and a spare knife, this cutter ensures smooth paper handling, high cutting accuracy, and efficient production workflow. A reliable and proven German-made machine, ideal for commercial printing houses.

Polar 66 Guillotine Cutting Machine – 2010

The Polar 66 (2010) is a precise and reliable automatic guillotine cutting machine designed for professional print finishing and post-press operations. Equipped with an air table, side tables, programmable control, and a spare knife, this cutter ensures smooth material handling, high cutting accuracy, and efficient workflow. A well-maintained German-made machine, ideal for commercial print shops and finishing departments.

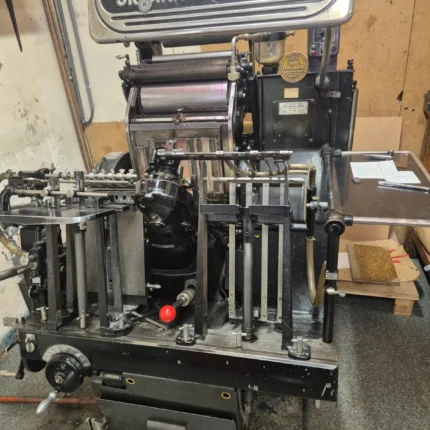

Heidelberg GT S Platen Printing & Die Cutting Machine

The Heidelberg GT S is a compact and powerful platen die-cutting machine, designed for small to medium-format applications requiring high pressure and precision. With a punching force of up to 60 tons and a maximum output of 4,000 sheets per hour, this machine is ideal for letterpress , die cutting, creasing, and specialty finishing work. A robust Heidelberg-built press, trusted for reliable performance and consistent results.

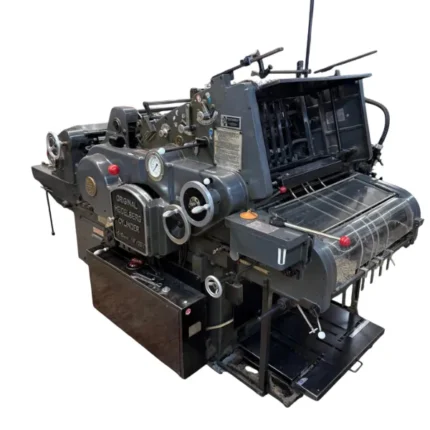

Heidelberg OHT Tiegel Platen Printing Machine – 1961

The Heidelberg OHT Tiegel (1961) is a classic platen printing and die-cutting machine, renowned for its legendary durability and mechanical precision. Designed for small-format high-pressure applications, this machine is ideal for letterpress printing, hot foil stamping, embossing, and die cutting. Equipped with the original Heidelberg inking unit and supplied with chases, it delivers reliable performance with a maximum speed of up to 5,500 sheets per hour. A timeless Heidelberg machine, highly valued for specialty printing and finishing applications.

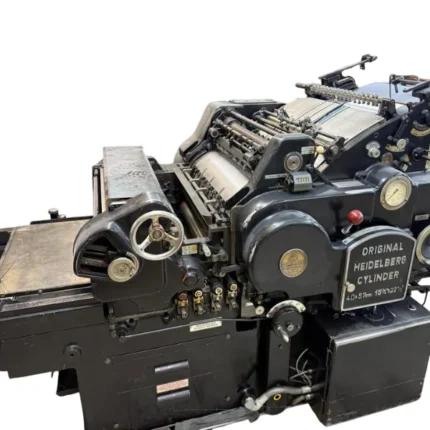

Heidelberg KSBA 46 × 58.5 Die Cutting Machine – 1961

The Heidelberg KSBA (1961) is a classic and highly reliable cylinder die cutting machine, widely recognized for its precision and durability in die cutting and creasing applications. Equipped for die cutting, this machine is ideal for packaging, carton, and specialty print finishing. With its solid mechanical construction and proven Heidelberg engineering, the KSBA remains a trusted solution for professional finishing operations.

Heidelberg OHT Hot Foil Stamping Machine

The Heidelberg OHT is a classic and reliable hot foil stamping machine designed for high-quality decorative finishing. Built with Heidelberg’s renowned mechanical precision, this machine is ideal for hot foil stamping on paper and board. Featuring the original Heidelberg hot foil system and A4 working size, it delivers consistent pressure and sharp stamping results for professional finishing applications.

Heidelberg SBG 56 × 77 Die Cutting Machine

The Heidelberg SBG 56 × 77 is a heavy-duty platen die cutting machine designed for high-precision cutting and creasing applications. Known for its exceptional mechanical strength and stable pressure, this machine is ideal for packaging, box making, and specialty finishing. With a working size up to 56 × 77 cm and a production speed of up to 4,600 sheets per hour, it is a reliable solution for professional die cutting operations.

Heidelberg KSB 40 × 57 Die Cutting Machine with Inking Unit

The Heidelberg KSB 40 × 57 is a classic platen-style die cutting machine equipped with an inking unit, suitable for precise die cutting and creasing applications. Built with Heidelberg’s renowned mechanical strength, this machine delivers stable pressure, accurate results, and long-term reliability. An excellent solution for packaging, box making, and specialty finishing operations.

Heidelberg KSD 46 × 64 Die Cutting Machine with Inking Unit

The Heidelberg KSD 46 × 64 is a classic and robust die cutting machine equipped with an inking unit, making it suitable for both die cutting and creasing applications with printed or plain sheets. Designed for precision and durability, this machine delivers reliable performance at speeds up to 5,000 sheets per hour. A proven solution for packaging, box making, and specialty print finishing operations.

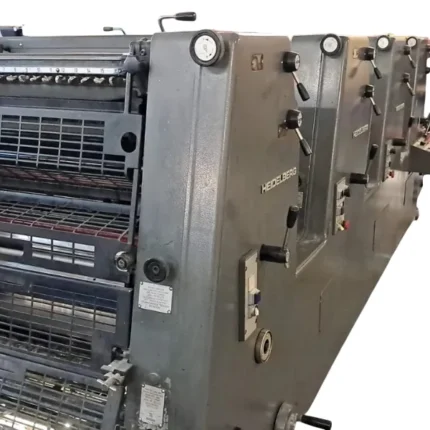

Heidelberg GTO 52-4P+ 4-Color Offset Printing Machine – 1990

The Heidelberg GTO 52-4P+ (1990) is a compact and reliable 4-color sheetfed offset printing machine, ideal for small to medium commercial printing operations. Equipped with Aquatron dampening, Weko powder spray, double sheet control, and Plus version configuration, this press delivers consistent print quality, stable operation, and efficient daily production. With approximately 52 million impressions, it remains a dependable solution for jobbing and short to medium runs.

Heidelberg SM 74-5PH 5-Color Offset Printing Machine – 1997

The Heidelberg Speedmaster SM 74-5PH (1997) is a reliable 5-color sheetfed offset printing machine, designed for high-quality commercial printing. Equipped with Autoplate, Alcolor dampening, CPC 1.04 ink control, CPTronic console, Technotrans cooling, and full automatic wash-up systems, this press delivers stable color consistency, efficient makeready, and dependable performance. With approximately 129 million impressions, it remains a proven solution for professional print houses.

Ryobi 756 6-Color Offset Printing Machine – 2006

The Ryobi 756 (2006) is a dependable 6-color sheetfed offset printing machine designed for high-quality commercial production. Featuring Ryobimatic dampening, PQC control, PCS-G remote console, and comprehensive automatic wash-up systems, this press delivers stable color control, efficient makeready, and consistent output. A well-maintained machine with approximately 66 million impressions, ideal for professional print houses.